PRODUCT LIFETIME VALUE

Designed for the long haul

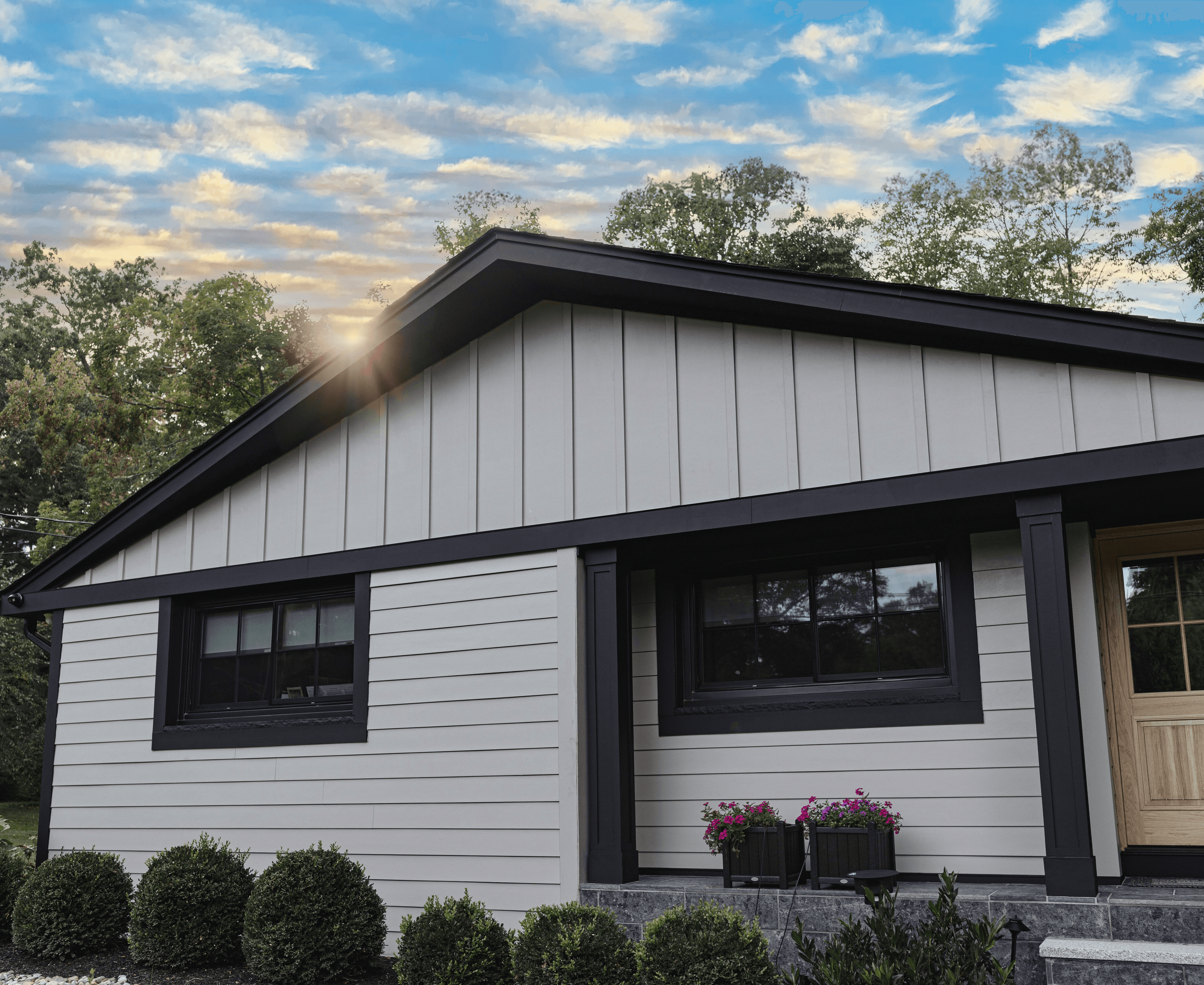

When you choose Hardie® fiber cement products, you get long-lasting beauty, unmatched value, and an industry-leading warranty that has your back. That’s why Hardie® siding has earned its title as the #1 brand of siding in North America*

Ready for total peace of mind?

Re-siding with fiber cement siding is one of the top ways to increase your home’s re-sale value,** making it the smart choice. We’re proud to manufacture fiber cement products with superior durability—so you can count on serious staying power over time.

Lasting color

ColorPlus® Technology finishes are engineered to last longer than paint applied on the jobsite and to resist chipping, peeling, cracking, or fading—saving on maintenance efforts, year after year.

Cost savings

Fiber cement costs less than wood siding and resists fire, water, weather, pests, and more—meaning your money goes further. And many insurance companies offer reduced premiums for homes with fiber cement siding.

Climate resilience

Only Hardie® fiber cement products are Engineered for Climate® to provide the best performance specifically for the weather in your region.

We stand behind our products

Unlike other companies, we don’t prorate our Hardie® substrate warranty coverage. All Hardie® siding, trim boards, and soffit products are backed by a transferable 30-year, non-prorated substrate limited warranty. And our ColorPlus® Technology finishes come with a 15-year limited warranty that covers paint and labor, protecting against peeling, cracking, and chipping.

Demonstrating what's possible

Though long-lasting beauty transcends aesthetics and styles, rebuilding historic homes to be future-ready pose unique challenges. Clad entirely with Hardie® siding and trim, the Queen of Zero project demonstrates its possible to retain an historically accurate look while remaining resilient against damage from harsh mid-Atlantic winters and natural disasters.Read moreHaving something we knew would last and would still look good for a long time was a huge factor in our decision.

Chris and Minna Z.

Homeowners

Bring a lifetime of value to your home

Elevate your home’s style and function with our hardworking products.