Innovation

Our global strategy is to develop Homeowner Focused, Customer and Contractor Driven™ innovation that addresses unmet needs while expanding our portfolio of products. Insights from homeowners, customers, and contractors play an important role in helping us develop new and innovative solutions that improve the lives of homeowners. By applying a mindset of continuous improvement to research and product development, we deliver superior value to our customers. This helps end users build better homes and more sustainable communities.FY25 Innovation highlights

Every product in and around the home has an impact, and we know that it is possible for all homes to be future ready. We strive to be proactive, innovative and adaptable in a rapidly changing landscape, while providing durable, resilient and low maintenance solutions that can withstand a variety of climate conditions and weather extremes.

MINIMIZE OUR IMPACT

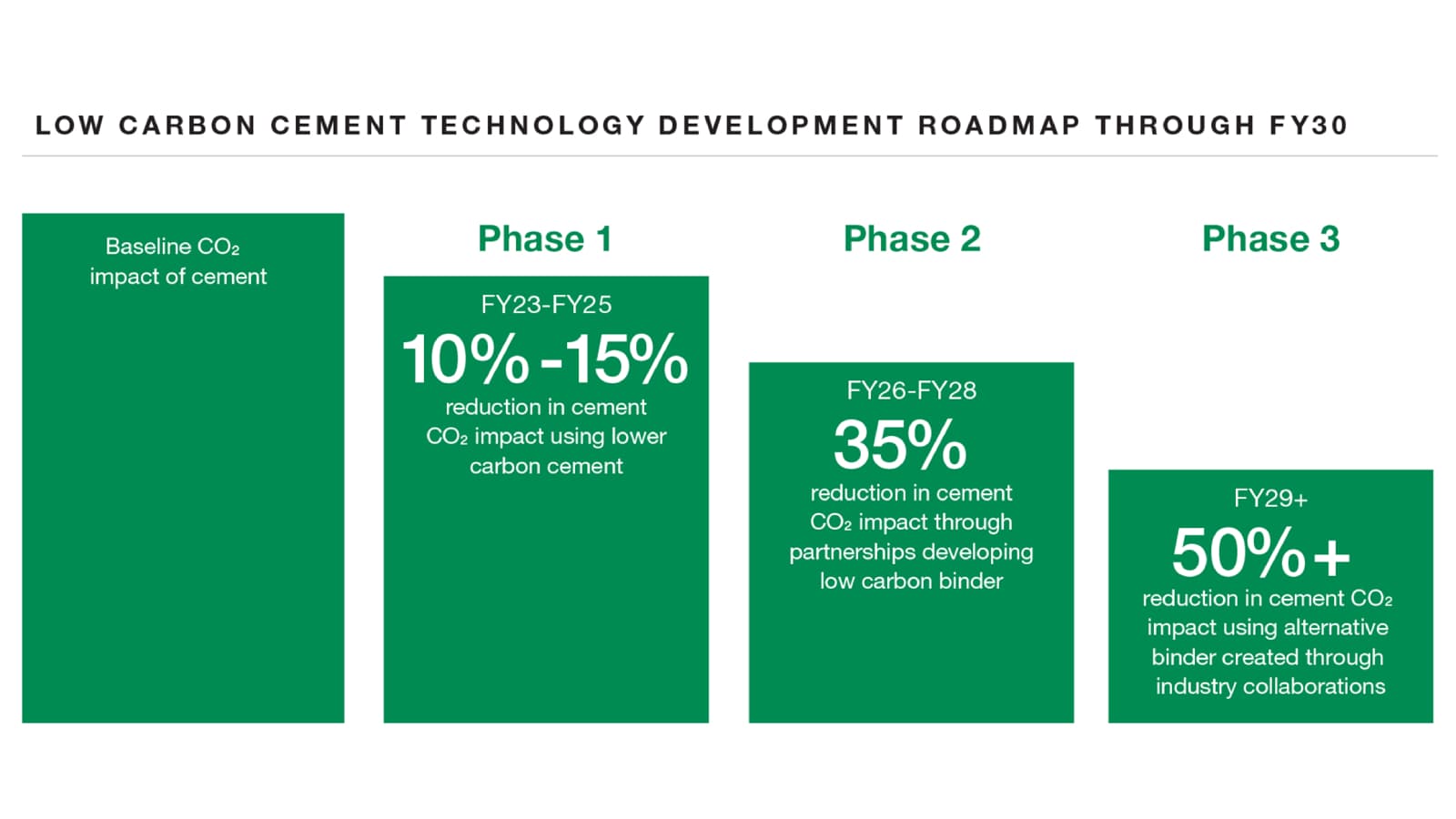

Advancing our Low Carbon Cement Technology Roadmap

Based on the path we charted to reduce our Scope 1+2 greenhouse gas (GHG) emissions and work toward net zero by 2050, we continue to focus on one of our biggest levers — natural gas efficiency in our facilities. We reduced our CY24 Scope 1+2 emissions by 14% from our CY21 baseline. This reduction reflects a combination of lower volumes, ceasing operations in the Philippines, grid decarbonization and internal projects, including our transition away from coal.

SUSTAINABILITY IN ACTION

Saving costs by reducing natural gas use

Julian’s precision and innovation reduced natural gas usage per standard meter of board produced by 10% in Münchehof, Germany. This work is anchored in HMOS driving long-term sustainable results. Building on the success of his work, this initiative will be implemented in Orejo, Spain.

BUILDING PRODUCTS MADE TO LAST

2025 Sustainable Product of the Year

Green Builder magazine recognized James Hardie as a green innovation and brand leader for the second year in a row, naming Hardie® Artisan Trim as a 2025 Sustainable Product of the Year. Each year, Green Builder spotlights products that are more resilient or more resource efficient in the manufacturing process, rewarding manufacturers that encourage sustainability through innovative technology. In addition to reappearing on the Sustainable Products of the Year list this year, James Hardie was named the “Greenest Siding Brand” in the Green Builder® annual Readers’ Choice survey for 2020, and was also recognized as one of the Green Builder® Eco Leaders for 2024.

INNOVATION

Showcasing beauty that stands the test of time

James Hardie collaborates with leading architects and builders to demonstrate the modern standard of performance and beauty, while innovating to ensure our durable products can withstand a variety of climate conditions and extremes. In 2024, we worked with builders to spotlight three resilient homes in the Mountain, Midwest and Mid-Atlantic regions. In 2025, we were part of new and renovated home projects with leading architects and builders from Texas and Minnesota, in partnership with GreenBuilder Media and ProTradeCraft. In Austin, Texas, Green Builder Media, along with Barley | Pfeiffer Architecture, is constructing the VISION House Austin. The home’s climate responsive design features Hardie® Artisan® Siding and Hardie® Artisan® Trim fiber cement products, which offer design features that set the home apart.Explore Vision House Austin

Three resilient homes for the future

James Hardie is providing solutions to homeowners, builders and designers to address the challenges presented by a changing climate. Our products were selected by three leading home builders from across the U.S. in FY25. Each project is unique, but what they have in common is the incorporation of more durable and resilient solutions delivered through Hardie® products.