INDUSTRY-LEADING DURABILITY

Siding that stands up to the elements

Hardie® fiber cement products resist damage from external fire, water, weather, pests, and time—helping protect your most precious asset for the long haul.

Help harden your home against unexpected damage

Fire

Hardie® fiber cement siding will not ignite when exposed to a direct flame —nor contribute fuel to a fire.* In contrast, fire feasts on wood and melts vinyl almost instantly.

Moisture

Hardie® products are engineered to resist water and humidity—and will stand up to rain, sleet, and snow.

Weather

Hardie® products are made to withstand severe weather: hurricanes, rainstorms, strong winds, extreme heat, UV rays, humidity, snow, hail, freezing temperatures, and more.

Pest

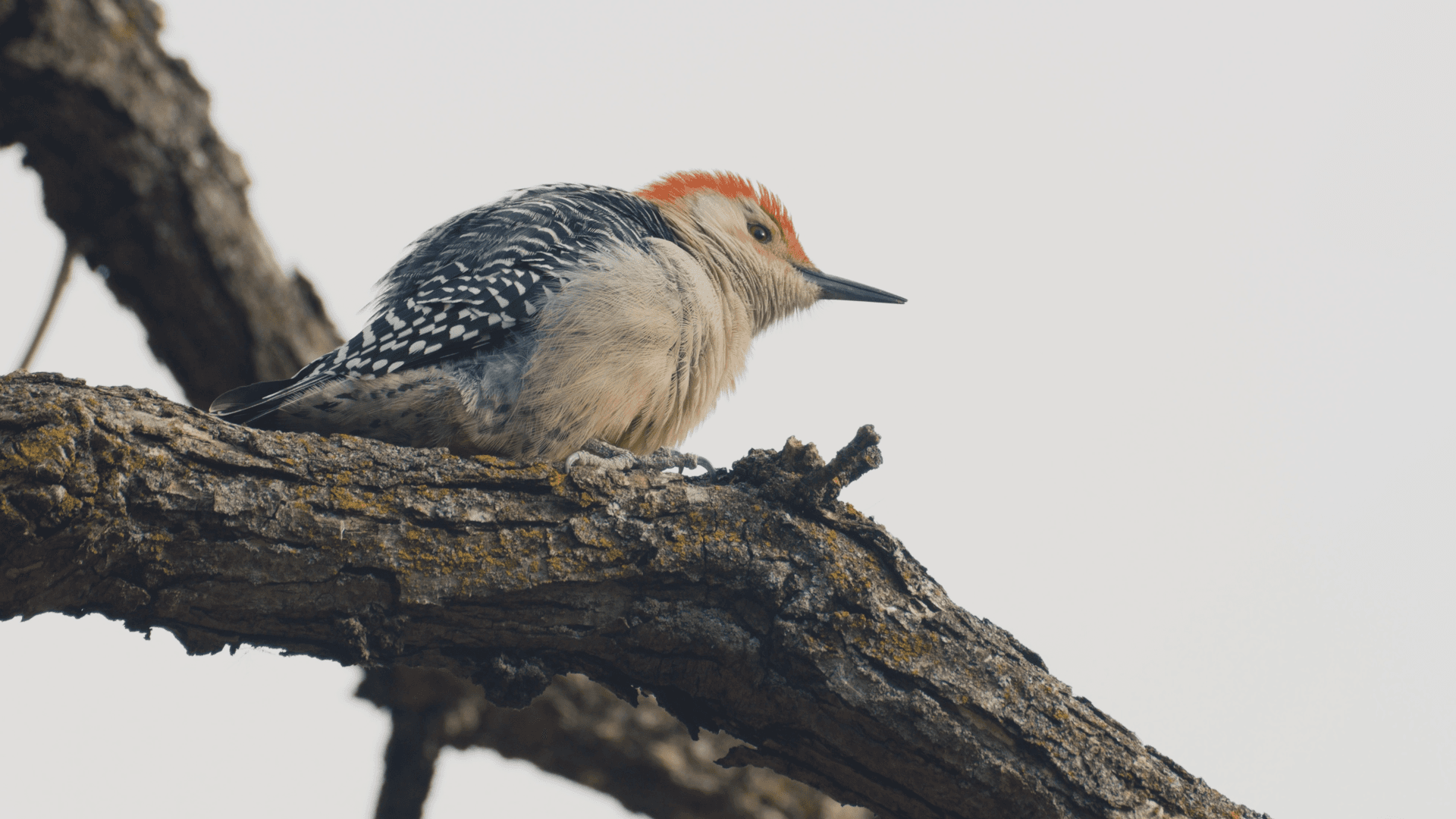

Hardie® siding holds little appeal for woodpeckers, termites and other wood-boring insects and pests.

Hardie® Fiber Cement Siding standing up to the extreme

James Hardie conducted a fire demonstration to show the noncombustible properties of Hardie® fiber cement siding. See how it stacks up to other siding materials for yourself.Mother nature meets her match

Only Hardie® fiber cement products are Engineered for Climate® to ensure you get unmatched performance. Designed to defy harsh weather in your specific area, Hardie® siding stands up to blistering sun, hurricane-force winds, humidity, snow and more.

Color that looks better—and lasts longer

With our proprietary ColorPlus® Technology finishes, you get more than gorgeous color—you get long-lasting character. Our factory-applied, baked-on color creates a strong bond that resists peeling, chipping, and cracking for years to come.

Why choose James Hardie?

As the trusted industry leader, James Hardie provides distinct style, high performance, next-level innovation, and long-lasting value.

Put our products to the test

Explore our catalog to discover why homeowners and pros alike choose Hardie® products.