Zero Harm

We prioritize safety globally through our Zero Harm standards and our commitment to continuous improvement. Safety is embedded in our corporate culture, and we work diligently 24/7 to ensure the protection of our people and those who use or interact with our products. Our Global Code of Business Conduct guides our actions to ensure we do the right thing by acting ethically, fairly, and with integrity.Committing to a Zero Harm culture

Zero Harm reflects our conviction that every incident is preventable through changing behaviors. We address Zero Harm through a focus on safe people, safe spaces, and safe systems.

Safe people

• SafeStart: A behavioral-based safety awareness and skills development system • Rate Your State: A peer-to-peer program to build & sustain safety-minded behaviors • Safety observations and accident reporting shared with all regions

Safe spaces

• Clearly defined responsibilities and authority to stop work for safety concerns • Visual management tools to clearly communicate and simplify processes • Standardized global signage and color coding to easily identify safety risks

Safe systems

• Hardie Manufacturing Operating System (HMOS) to discuss concerns and solutions • Annual audits and reviews to inform improvement around critical safety risks • Safety Steering Committees and weekly safety meetings at global, regional and local levels

FY25 Zero Harm highlights

We consider safety everyone’s responsibility and work diligently 24/7 to ensure the protection of our people and those who use or interact with our products. We believe that every incident is preventable, and we work toward Zero Harm through a focus on safe people, safe places and safe systems.

CONTINUOUS IMPROVEMENT

Investing in safety

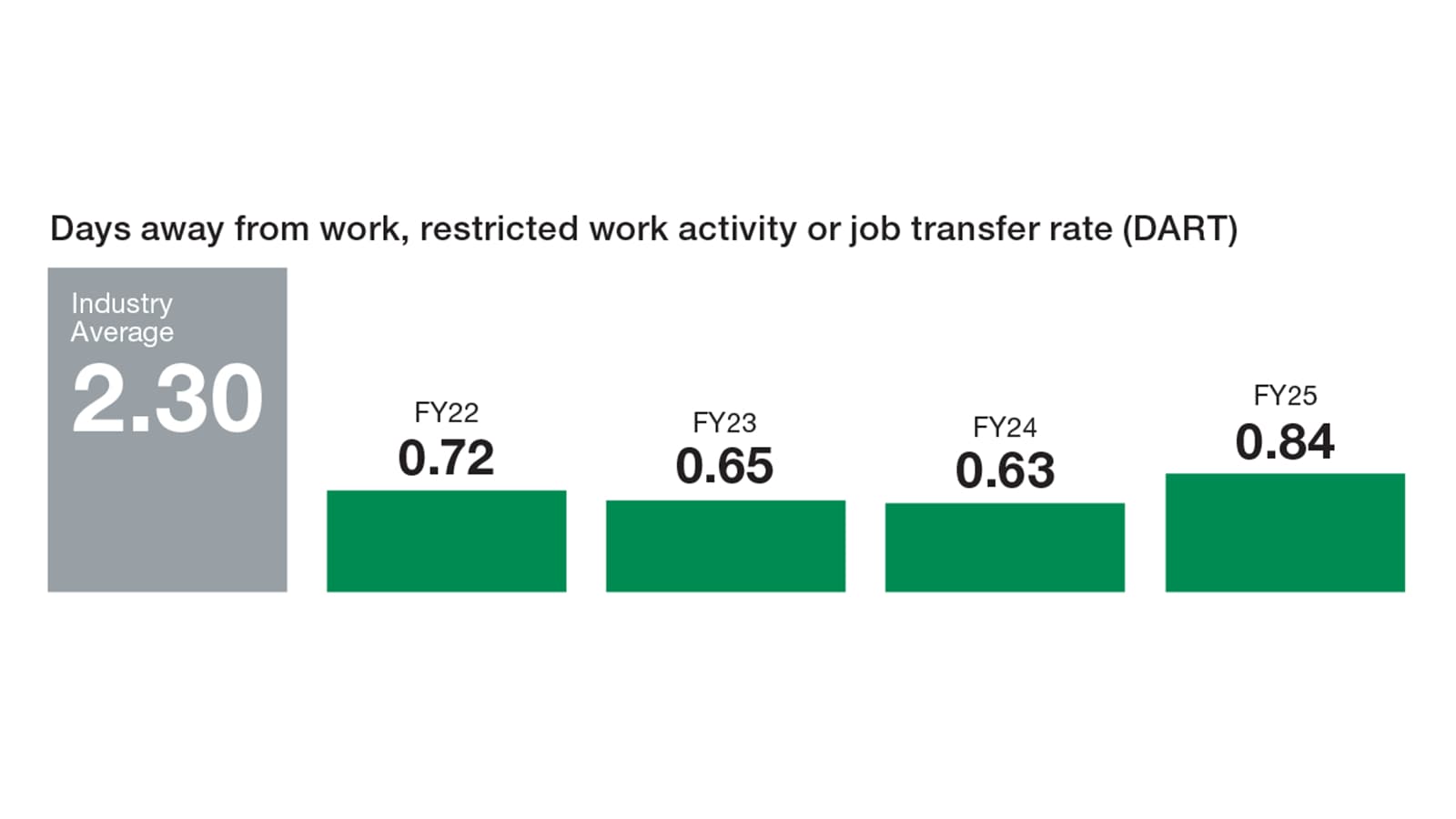

Over a three-year period, we are investing more than $75 million in strategic safety infrastructure projects globally. We are upgrading safety equipment as part of our focus on the areas of highest risk for our employees: working from heights, machine guarding and energy control processes. Our engineered solutions also include special attention to the control of hazardous energy. While our overall FY25 DART rate remains well below the industry average, we acknowledge that it did increase from our FY24 rate and are exploring opportunities for improvement. We are actively addressing this through increased leadership engagement, continued execution of strategic safety projects and proactive risk mitigation on the plant floor.

SUSTAINABILITY IN ACTION

Safety Ownership Starts with Me

Through 35 events during Zero Harm Safety Month, we brought our Zero Harm foundational imperative to life with a focus on our individual and shared accountability to maintain a safe working environment for ourselves and others. Global focus areas this year included fall protection, machine guarding, lockout tagout and mental health and wellness. Local events featured impactful keynote addresses targeted to each unique work environment in addition to a selection of 16 demonstrations all tied to critical risk and other key safety topics.

SUSTAINABILITY IN ACTION

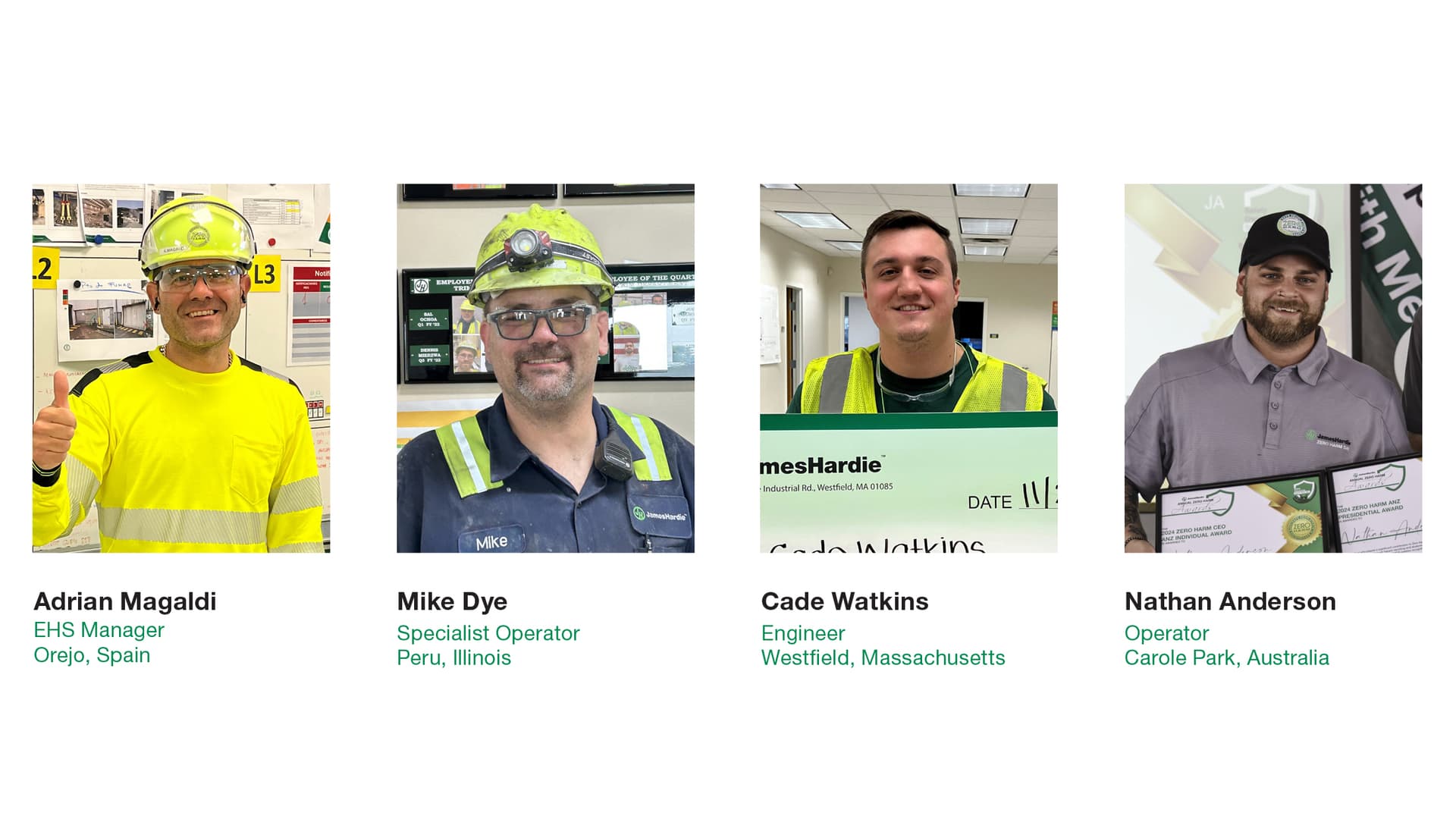

Recognizing exemplary safety leadership

To coincide with our Global Zero Harm Month, we presented our second annual Zero Harm CEO Awards to sites and individual employees from each region to recognize those who routinely go above and beyond when it comes to safety. Each winning site (Tacoma 2, Washington; Rosehill, Australia; and Orejo, Spain) demonstrated continuous improvement and increased engagement and consistently works to achieve established global standards in Zero Harm. Our individual winners demonstrated exemplary safety leadership and behaviors daily and are committed to the James Hardie Zero Harm philosophy.

SUSTAINABILITY IN ACTION

Advances in safety standards

In FY25, we installed sophisticated engineered fall arrest systems in all our North American plants. We also have made advances in machine guarding across the region. Machine guards provide protection for our employees while promoting risk awareness. Our Tacoma, Washington, plant installed guards in the entire sheet machine area, a first for the region, and is moving on to guarding in the cutting lines. Our APAC and Europe regions also completed machine guarding installations and upgrades to make working from heights safer; additional upgrades are planned there over the next two years.